Reclaim Over 50% of your Cost For CAUSTIC Chemicals Which is being wasted down your drains!

We have the technology that replaces the use of caustic soda to pH control water down your drain system and can save the refinery millions.

Reclaim Up To 60% of your Cost For CAUSTIC Chemicals Which is being wasted down your drains!

We have the technology that replaces the use of traditional caustic chemicals to pH control water down your drain network and can save the refinery millions.

PROBLEM

Accurate and reliable pH control is critical to refinery operations, as imbalances can disrupt processes, incur significant costs, and result in hefty environmental fines. The refinery currently relies heavily on caustic soda and soda ash to manage pH levels across various stages. One key area of focus is neutralizing acidic drain wastewater to protect drain pipe infrastructure and minimize environmental impact when releasing wastewater into the ocean.

_______________________________

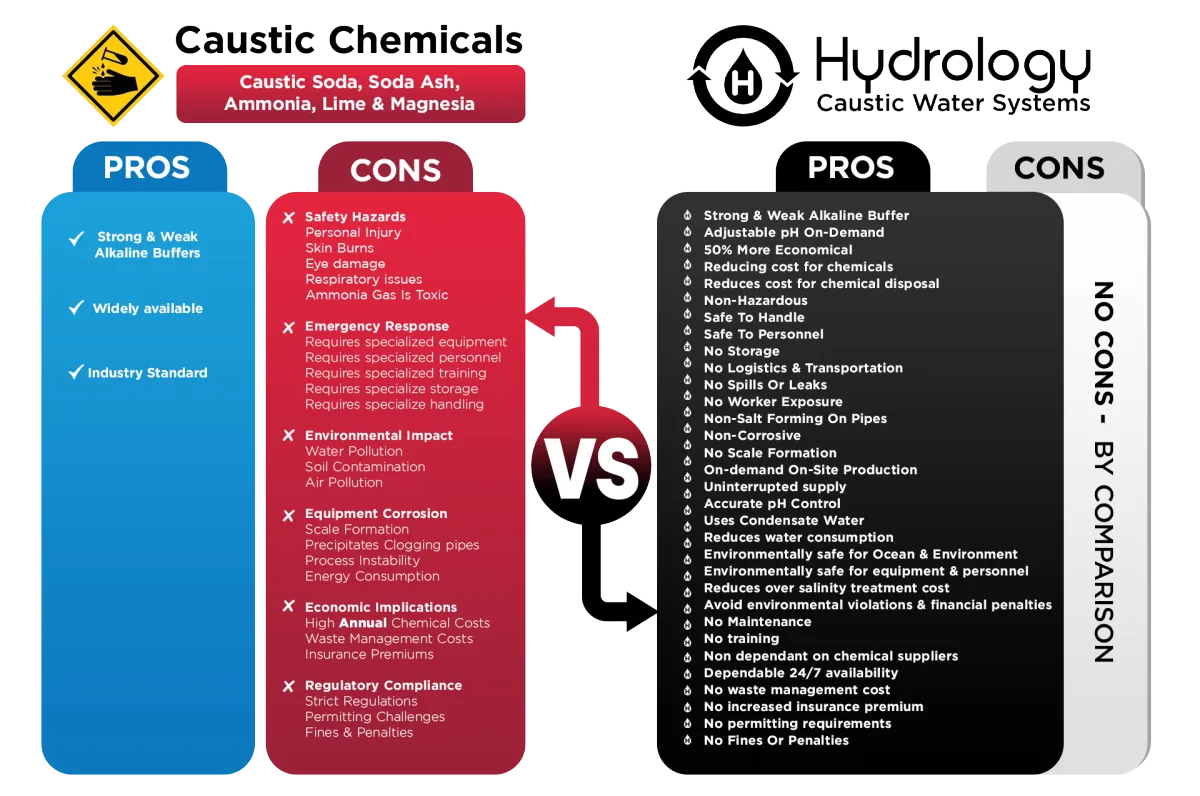

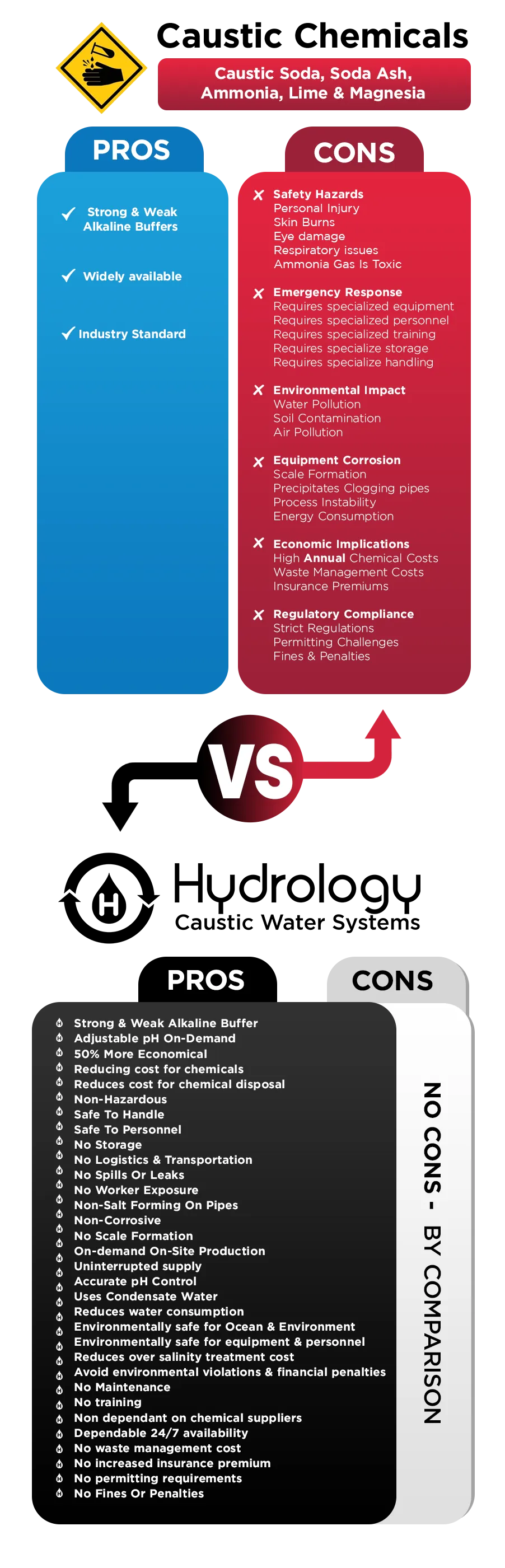

The dependency on caustic chemicals is costly, amounting to millions annually and posing safety, equipment, and environmental risks. This essentially flushes away resources that could be saved with a more economical option. Beyond the financial burden, using caustic chemicals presents additional challenges. Safety hazards associated with handling the chemicals, corrosive degradation of refinery equipment, and environmental concerns regarding disposal all contribute to the need for a more cost-effective and sustainable solution.

Sourcing & Logistics

High Mark-Up & Constant Purchasing: Chemical suppliers markup caustic chemicals for refineries more than other industries and constant purchasing adds up to millions annually.

Expensive transportation: Handling and shipping hazardous materials increases costs.

Storage and handling risks: Maintaining caustic soda and soda ash requires specialized equipment and safety measures, driving up operational expenses.

Supply chain vulnerabilities: Reliance on external suppliers creates potential disruptions and price fluctuations.

Waste Management Cost: Proper disposal and handling of caustic soda and soda ash contribute to overall costs.

Operational Challenges

Concentration Control: Maintaining consistent caustic concentration is essential for optimal pH adjustment and cost-efficiency. There is generally a 15% variance of chemical waste annually.

Safety Hazards: Handling caustic soda poses significant safety risks to workers, including burns and eye damage.

Equipment Corrosion: Prolonged exposure to caustic soda can damage refinery infrastructure.

Salt Formation: Using sodium chloride with caustic soda can lead to salt buildup and reduced system efficiency.

Wastewater Treatment Impact: Inefficient wastewater treatment can increase caustic chemical usage.

Environmental Impact

Overuse and Discharge:

Excessive use of caustic chemicals can increase the overall salinity of the wastewater stream discharged to the ocean impacting marine life.

Over Salinity: Oversalination of the wastewater adds complexity and additional cost for salinity treatment.

Regulations and Compliance:

Inconsistent pH control leads to caustic chemical waste and pH fluctuations, resulting in environmental violations, financial penalties and hefty fines.

Public Health Risks: Off Spec wastewater can pose potential health risks to humans through contact and recreational activities.

THE SOLUTION

Latest pH Control Technology

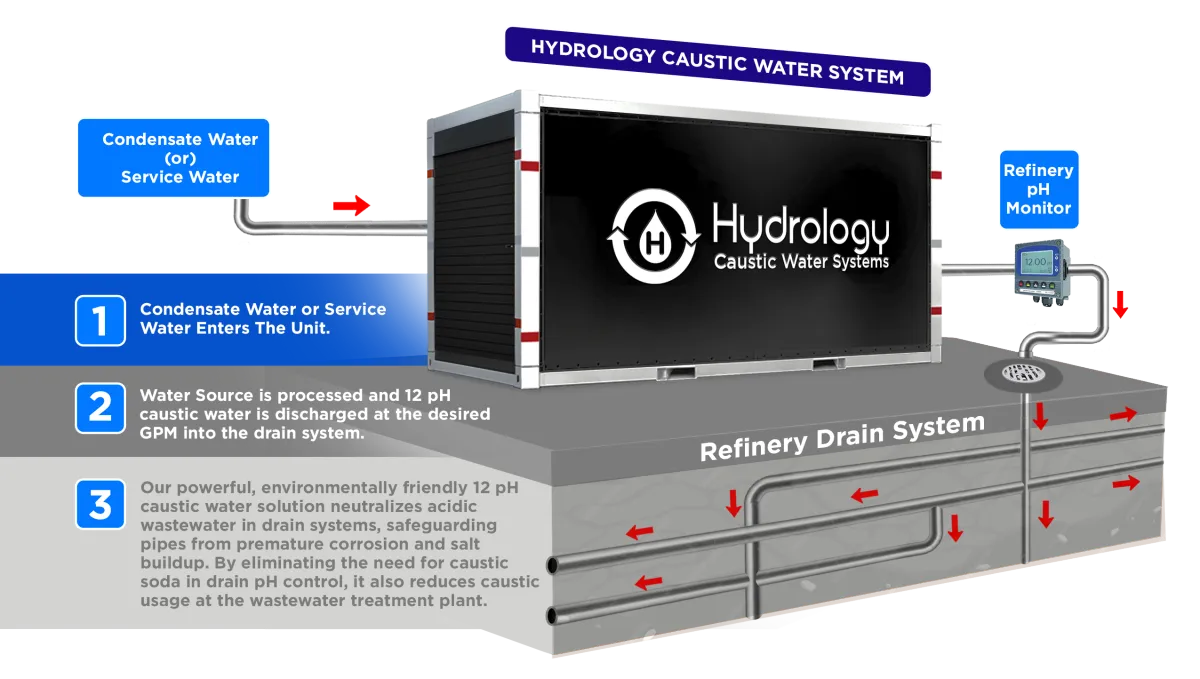

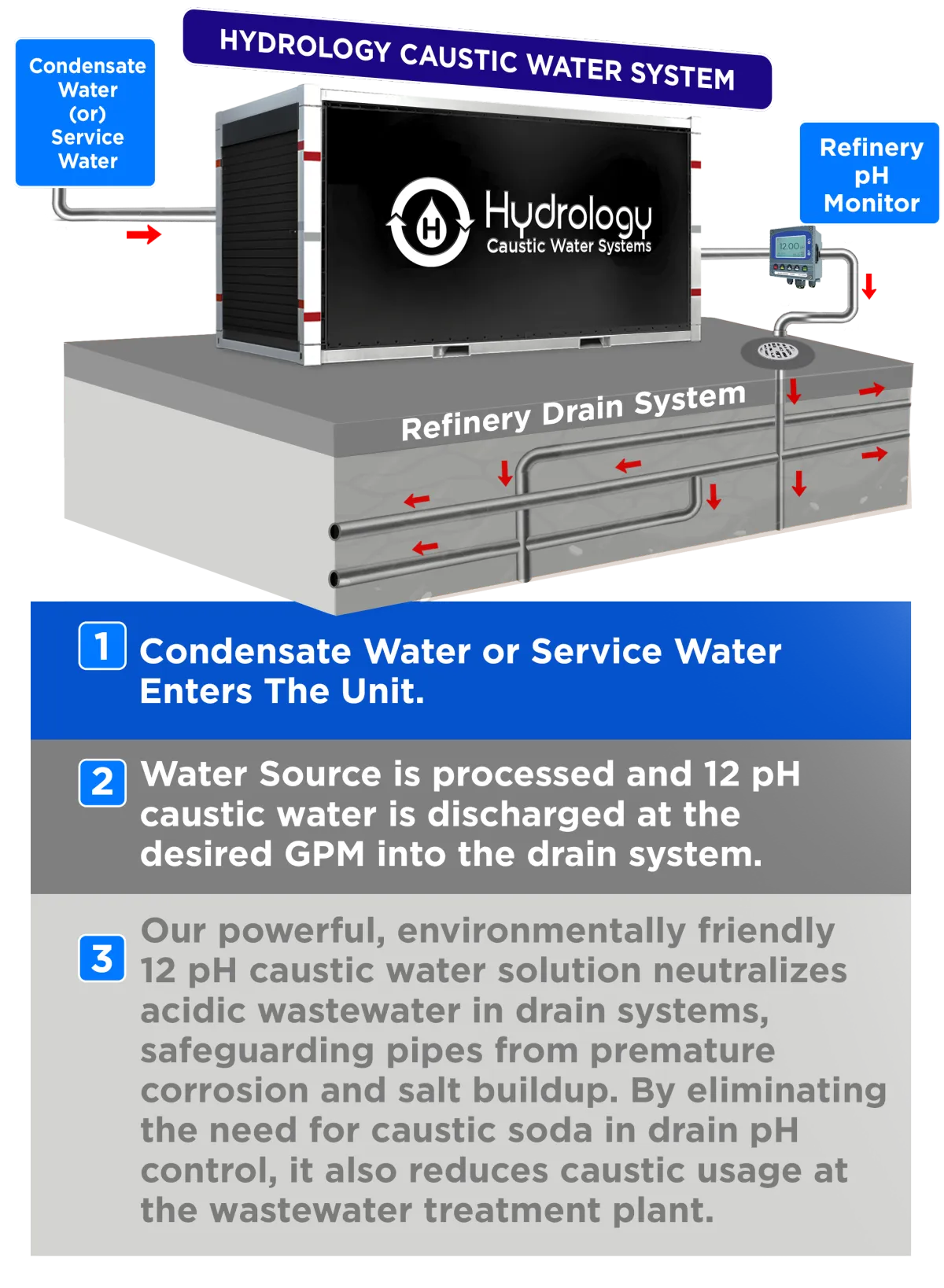

HYDROLOGY offers a groundbreaking approach to pH control, replacing traditional caustic soda methods. Our technology transforms readily available water sources into a potent, environmentally friendly Caustic Water with a powerful pH exceeding 12. This eliminates the hazards, costs, and environmental impact associated with caustic soda handling and disposal.

By generating caustic water on-demand, Hydrology ensures uninterrupted operations, reduces risks, and minimizes environmental footprint. Our automated system is designed for durability, efficiency, and zero maintenance to the refinery.

Transforming Water into pH Control Power:

Cleaner, Greener, Cheaper.

HYDROLOGY offers a groundbreaking approach to pH control, replacing traditional caustic chemical methods. Our technology transforms readily available water sources into a potent, environmentally friendly Caustic Water with a powerful pH exceeding 12. This eliminates the hazards, costs, and environmental impact associated with caustic chemical handling and disposal.

By generating caustic water on-demand, Hydrology ensures uninterrupted operations, reduces risks, and minimizes environmental footprint. Our automated system is designed for durability, efficiency, and minimal maintenance.

Benefits Of Hydrology

Caustic Water Systems

COST SAVINGS

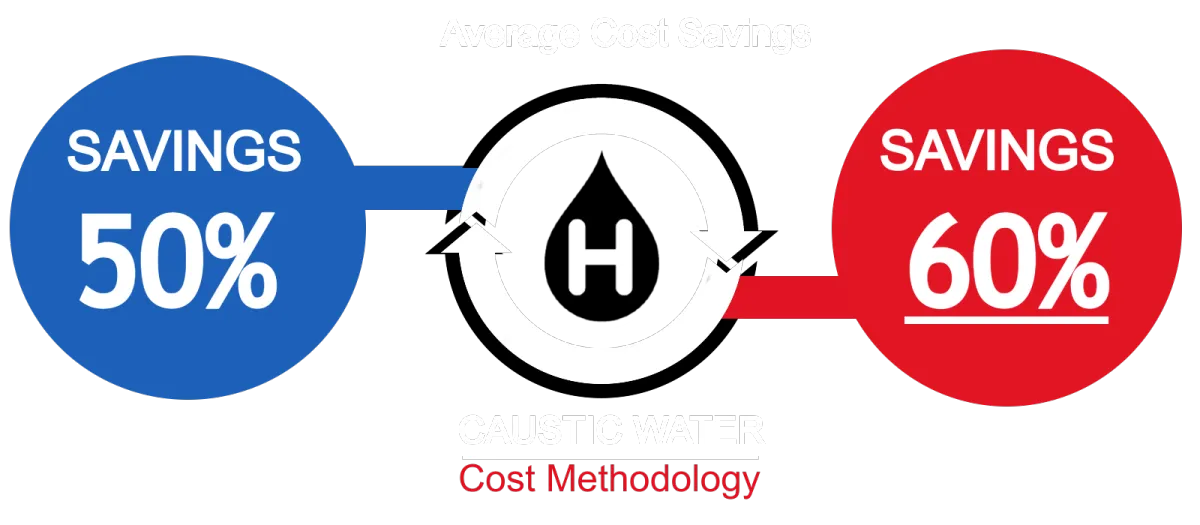

Slash Caustic chemical Costs by Up To 60%: Eliminate purchases, transportation, and storage expenses associated with hazardous caustic chemicals for drain pH control.

Eliminate Treatment and Disposal Cost: Our salt-free technology avoids the complexities and costs of managing additional wastewater salinity treatment.

Reduce & Streamline Expenses: Our system minimizes dependency on the supply chain and reduces maintenance and labor costs associated with traditional caustic chemical use.

No Waste Management Cost:

Hydrology Caustic Water has no waste by-product and is safe for the environment, personnel and equipment.

By Saving 50% To 60% You Increase The Bottom Line.

SAFETY & OPERATIONS

Enhanced Safety:

Minimize risks associated with transporting, storing, and handling hazardous caustic chemicals. Reduce the potential for spills, leaks, and worker exposure. Hydrology Caustic Water is safe for the environment, personnel and equipment.

Reduce Clogged Drain Piping & Premature Corrosion: Reduce reliance on Caustic chemicals and eliminate salt scale formation and corrosion on piping contributing to a more efficient operation.

Operational Efficiency: On-Demand, On-Site Accurate pH Control. Generate Caustic Water exactly when and where you need it, ensuring a reliable, uninterrupted supply.

ENVIRONMENTAL

Reduced Water Consumption:

Utilize condensate water for caustic generation, promoting water conservation efforts.

Environmental Protection:

Reduce over-salination and off-spec wastewater, minimizing marine pollution and protecting aquatic ecosystems.

Regulations and Compliance:

Minimizing inconsistent pH control fluctuations will avoid environmental violations, financial penalties, and hefty fines.

Public Safety: Safeguards public health by preventing water contamination.

Reduce Environmental Footprint

PROS & CONS

PROCESS

SMART, EFFICIENT & DEPENDABLE PERFORMANCE!

SMART, EFFICIENT & DEPENDABLE PERFORMANCE!

COST

Average Savings Are between 50% to 60% Based On The

GPM Of Caustic Water Required To Reach Desired Target pH.

Average Savings Are between 50% to 60% Based On The GPM Of Caustic Water Required To Reach Desired Target pH.

ABOUT US

Our team brings over 60 years of combined experience in commercial and industrial water purification and mineralization technology. We specialize in developing high pH-producing equipment, having successfully launched a dozen brands utilizing this technology since 2009.

Our team encompasses a diverse range of experts, including seasoned water quality process specialists, electronic automation engineers, and petrochemical operations veterans. We possess deep knowledge of regulatory compliance and operate a state-of-the-art equipment fabrication facility.

SCHEDULE A CALL

© Copyright 2024. Hydrology Systems. All rights reserved.