Commercial Alkaline Water Systems For Bottling Plants

Increase Plant Revenue With Alkaline Water For The Lowest Cost Possible!

Over a decade of proven process technology and reliability in alkaline water production for the smartest bottling plants in the industry.

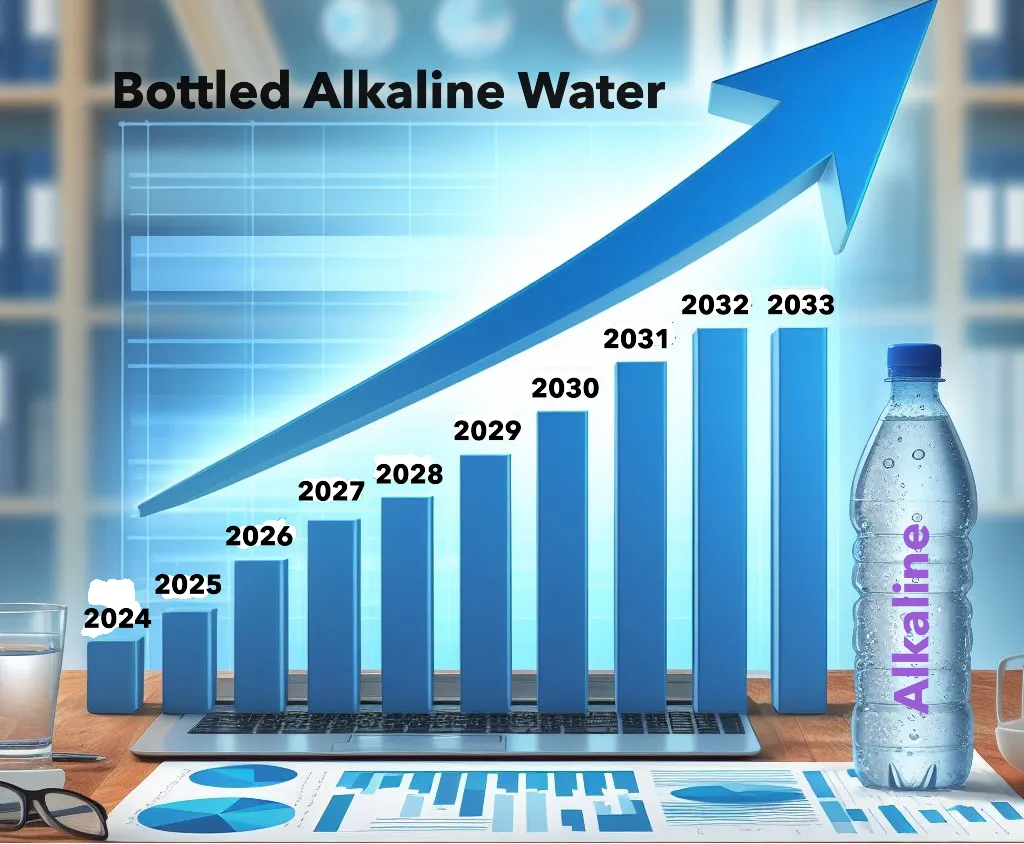

Market & Potential

4.7 BILLION & GROWING

The Niche Alkaline Water Market Continues To Grow Globally With The Market Conservatively Estimated To 15 Billion By 2030.

Consumer demand for healthier options in functional beverages continued to soar. The functional water market

is witnessing significant growth, projected to expand at a CAGR of 6.2% from 2023 to 2033, reaching a value of USD 27,281.72 million by 2033.Retailers continue looking for private label Alkaline water options to increase their offering.

Capitalized on existing customers by offering quality high-pH water to their portfolio.

Add new customers to your line by offering an alkaline water option.

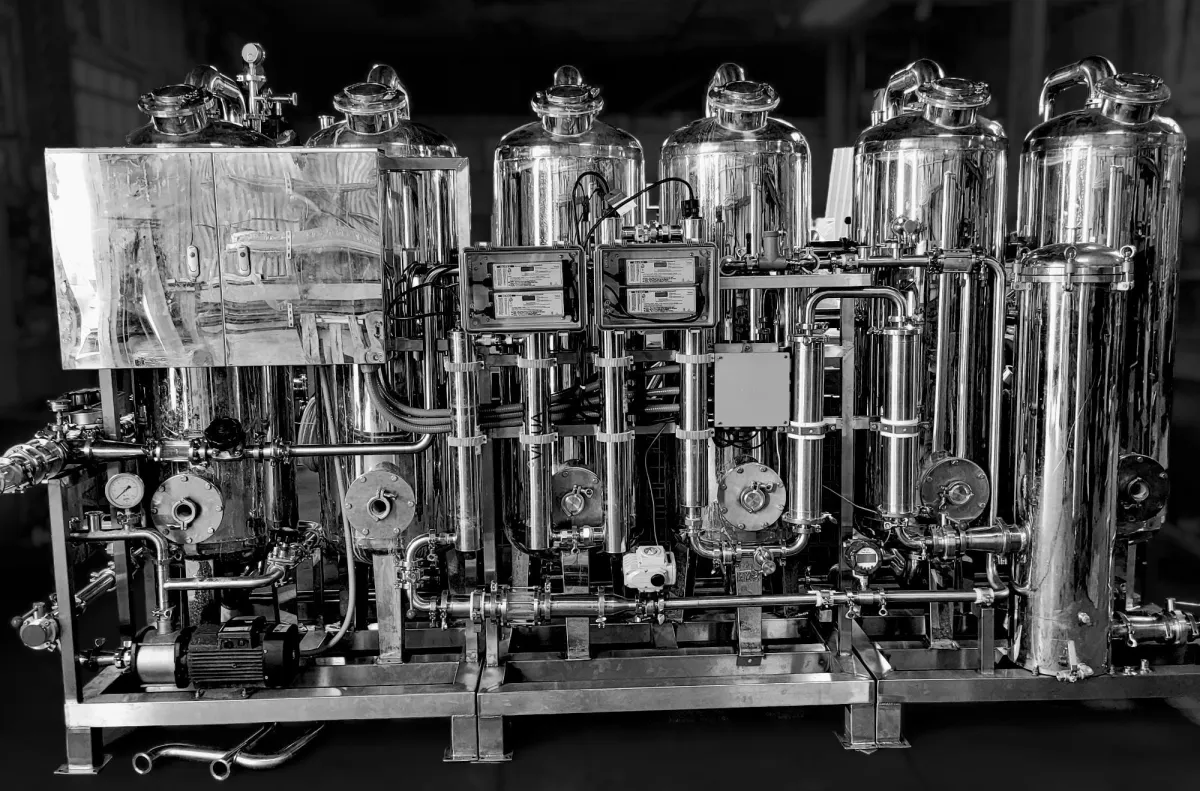

Technology

Proven -Reliable-Efficiency

Established track record of reliability and quality with co-packers and retailers for dozens of private-label brands Since 2012.

ONE OF ITS KIND!

The only zero-waste fully automated high volume capacity natural minerals ionization technology for making alkaline water available today. No need for chemical concentrates or water electrolysis process. Highly scalable, smart automation, proven, reliable and efficient built to last forever.

Proven

The most reliable, low-cost option available in the bottled water market today!

Makes A Strong & Stable 9.5 pH Alkalinity with a proven track record backed by a 7-year Stability Study.

Eco-Friendly Zero Waste Water Process (More Efficient & Reliable Than Electrolysis)

Reliable

10 Years Proven Safety and Quality Track Record. (FDA & GMP)

Technology prohibits microbials growth or sediments out of solution. (Thus preventing floaters and potential recalls).

Title 21 Water Quality Report Friendly & NSF Material Certification

Efficiency

Expansive upgradeable capacity to satisfy the production demand of any size plant built to last forever.

Custom form factor design to fit in any available plant space indoors or outdoors.

Meets all safety requirements per FDA and GMP.

The Difference

Concentrates & Electrolysis VS Mineral Ionization

Chemical Concentrates

Caustic harsh artificial chemical solutions that are highly corrosive and can cause severe burns to the skin and eyes upon contact

Caustic alkaline chemicals are not good for your health with long-term consumption as the chemical composition are basically a mix of industrial chemicals in low dosage. The main chemical being potassium hydroxide which is used as a drain cleaner in high concentration

Liability of deceitful marketing if advertised as a better healthy alternative water

Taste is subjective and not smooth

Hard to scale production if you don't have the room store the accumulation of liquid totes and pallets

Additional expense of transporting and shipping the liquid concentrate to the plant

This method serves small scale production only

Risk of over dosing chemicals like the

REAL WATER alkaline water brand

catastrophe causing consumer death

Risk of solids separating out of solution creating floaters and a potential recall which in many cases bankrupts companies

Electrolysis

Very Expensive Option From $200K to $300K+

Electrolysis utilizes similar caustic artificial chemicals solution like the chemical concentrate method

This method additionally uses electricity to separates water into two streams with a waste water factor of 10% to 30% adding cost

The waste water stream of 10% to 30% is highly acidic and needs to be neutralized with more chemicals before discarding in the drain to avoid fines from the water district

Caustic alkaline chemicals are not good for your health for long-term consumption as the solution is basically a mix of industrial chemicals in low dosage. Main chemical is potassium hydroxide which is used industrially as drain cleaner

Chemical solutions are highly corrosive and can cause severe burns to the skin and eyes upon contact

Liability of deceitful marketing if advertised as a better healthy alternative water

Risk of over dosing chemicals like the

REAL WATER alkaline water brand

catastrophe causing consumer death

Taste is subjective and not smooth

Additional expense of shipping and storing the liquid concentrate mix

Risk of solids separating out of solution creating floaters and a potential recall which in many cases bankrupts companies

Mineral Ionization

Low cost as compared to Electrolysis and Chemical Concentrate options

NO liquid chemical concentrates needed

NO need to store liquid totes of pallets that take up room

ZERO Waste Water Factor - 100% of water in becomes alkaline water

No need to neutralize waste to the drains as there is no waste to discard

NO Electrolysis process required

Alkaline water is made by mineral ionization that is safe with health benefits long-term

No risk of over-dosing or health risk

No risk of mineral floater separating out of solution

Smooth silky taste your customer will love

No risk to employees of chemical burns as minerals are safe for humans and plants

highly scalable for any size production volume

Low-cost maintenance and process

Easy to operate as it has its own smart-logic program

Can be operated remotely with PC or phone

Data logging for Quality Control record keeping

Minerals are NSF certified

Natural Minerals are FDA G.R.A.S

Equipment form-factor design can accommodate custom footprint to fit in any size plant

Equipment

Standard

MODEL AMS - 80

PRICE: $$$

SPECIFICATION

ZERO WASTE WATER Proprietary Process

PRODUCTION CAPACITY: -- Blocked---

DESIGN: Modular Expandable Form Fitted Size To Fit Every Plant

STRUCTURE & MATERIAL: All custom vessels, piping, and fittings are made from 304 & 316 electropolished sanitary stainless steel with a mirror finish.

SMART LOGIC: ------- Blocked------

PUMPS & DRIVES: -------Blocked -----

DISINFECTION SYSTEM: --- Blocked---

ELECTRICAL POWER SPECS:-- Blocked--

SAFETY FEATURES: ----- Blocked----

PROCESS AUTOMATION: ----- Blocked-

OFFSITE CONTROL & MONITORING SYSTEM: ---- Blocked----

Premium

MODEL AMS - 120

PRICE: $$$

SPECIFICATION

ZERO WASTE WATER Proprietary Process

PRODUCTION CAPACITY: -- Blocked---

DESIGN: Modular Expandable Form Fitted Size To Fit Every Plant

STRUCTURE & MATERIAL: All custom vessels, piping, and fittings are made from 304 & 316 electropolished sanitary stainless steel with a mirror finish.

SMART LOGIC: ------- Blocked------

PUMPS & DRIVES: -------Blocked -----

DISINFECTION SYSTEM: --- Blocked---

ELECTRICAL POWER SPECS:-- Blocked--

SAFETY FEATURES: ----- Blocked----

PROCESS AUTOMATION: ----- Blocked-

OFFSITE CONTROL & MONITORING SYSTEM: ---- Blocked----

SELF-CLEANING LOGIC: --- Blocked---

AIR ASSISTED CATALYST LOADING & UNLOADING: ---- Blocked----

MINERAL CATALYST: ---- Blocked----

MEGATRON

MODEL AMS - 200

PRICE: $$$

SPECIFICATION

ZERO WASTE WATER Proprietary Process

PRODUCTION CAPACITY: -- Blocked---

ENCLOSURE DESIGN: WEATHER PROOF HOUSING Reinforced Internal metal frame and waterproof fully weather resistant enclosure. (Optional Temperature Control Environment)

STRUCTURE & MATERIAL: All custom vessels, piping, and fittings are made from 304 & 316 electropolished sanitary stainless steel with a mirror finish.

SMART LOGIC: ------- Blocked------

PUMPS & DRIVES: -------Blocked -----

DISINFECTION SYSTEM: --- Blocked---

ELECTRICAL POWER SPECS:-- Blocked--

SAFETY FEATURES: ----- Blocked----

PROCESS AUTOMATION: ----- Blocked-

OFFSITE CONTROL & MONITORING SYSTEM: ---- Blocked----

SELF-CLEANING LOGIC: --- Blocked---

AIR ASSISTED CATALYST LOADING & UNLOADING: ---- Blocked----

MINERAL CATALYST: ---- Blocked----

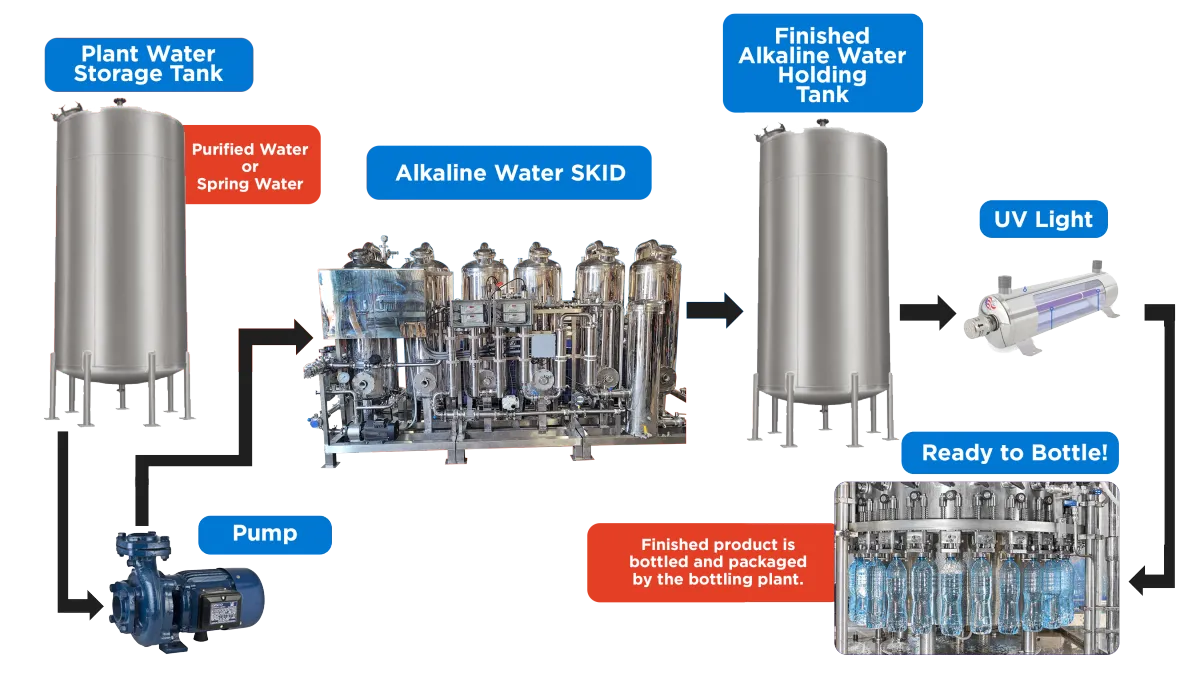

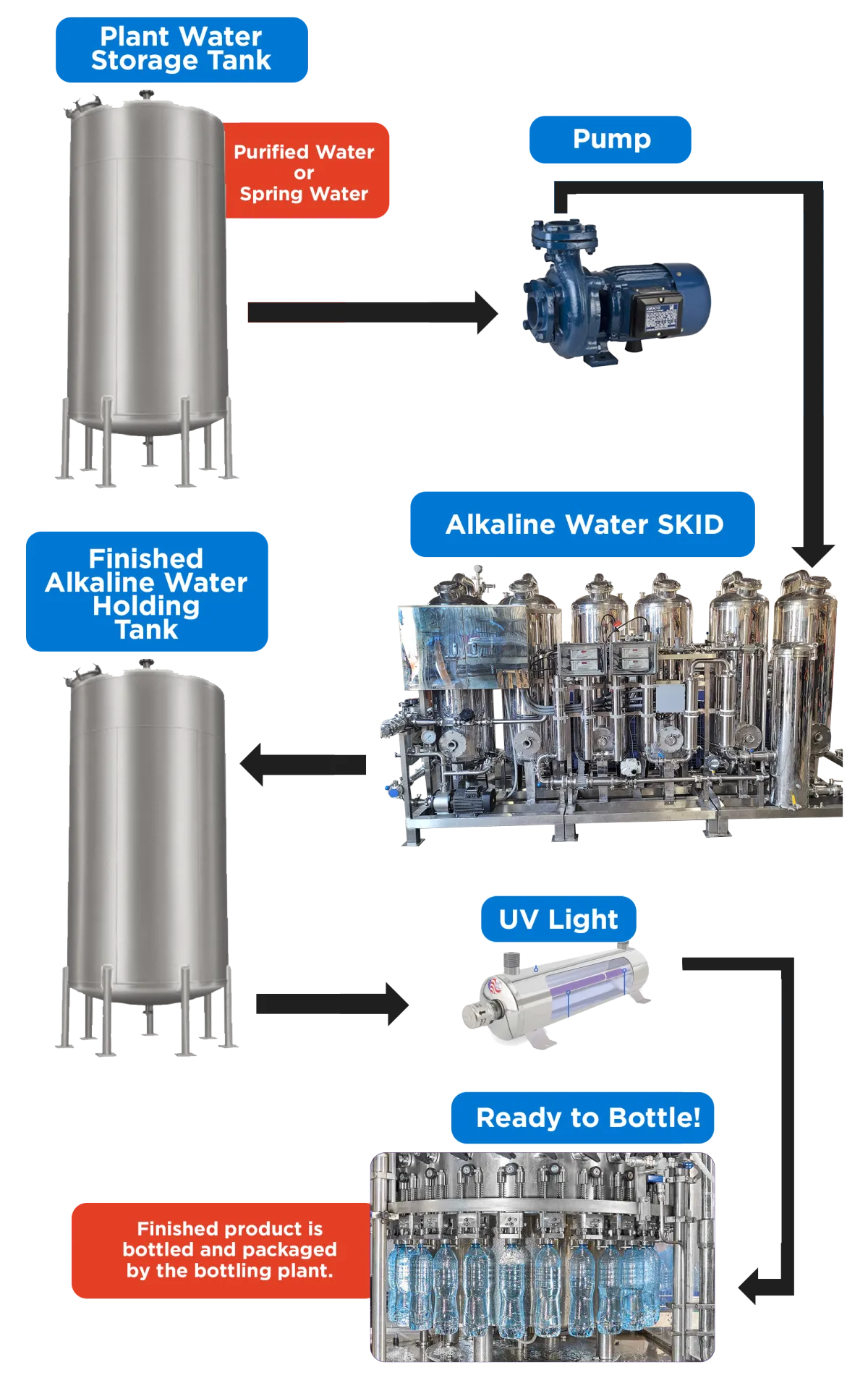

Process

SIMPLE INSTALLATION

Warranty & Financing

5 YEAR MAINTENANCE & SUPPORT

We stand behind our equipment with a 5 year warranty covering workmanship, parts, training and support. Our technician will be on site to install and ensure equipment operates as designed and will train personnel on-site. Additionally our technician will be on call to walk you through any issues and/or come back on site to ensure system is operating efficiently for the first five years.

PAY MONTHLY

Our systems are priced below our Electrolysis equipment competitors pricing and operated at the lowest cost in the industry delivering quality, efficiency and reliability. In addition to being the lowest cost option in the market today, we have partnered with selected financing companies to give you the best financing options available. In most cases, they will finance the entire amount with a monthly payment which can be easily managed by charging a portion of the finance fee included in your tolling rate.

About Us

60 Years Of Combined Experience

Our group is composed of a combined 60 years of experience in commercial and industrial water purification and mineralization technology, specializing in the last decade in alkaline water-producing equipment for water bottling plants. We have helped launch a dozen-plus brands in this industry since 2009. Our team covers all disciplines to develop the most advanced water technology today. Our crew boasts seasoned water quality process specialists, CAD designers, electronic automation engineers, beverage industry experts, regulatory compliance consultants, and state-of-the-art CNC and welding fabrication shops to deliver your new alkaline water system in a few weeks to 60 days, depending on the unit.

Schedule A Call

If you are looking for an alkaline water option for your plant or brand and want to learn how we can help get it done.

© Copyright 2024. Hydrology Systems. All rights reserved.